There have been myriad efforts from academia and industry to ramp up production of ventilators to ease potential shortages amid the pandemic. A partnership between General Motors and a Seattle medical device maker began producing ventilators at GM’s Kokomo, Indiana, plant late last month. The first shipment of those machines went to Chicago hospitals. Engineers at the University of Illinois at Urbana-Champaign have been working on a simple ventilator that could be plugged into hospital oxygen supplies and run without electricity.

The Fermilab team believes its machine, while also cheap and portable, is different because of its sophisticated software and controls.

“This is a ventilator designed for the ICU … optimized for COVID patients,” Brice said.

The Fermilab project started with physicists in Italy who were living through a spike of the pandemic there and hearing from doctors about the technical demands the disease placed on ventilators, according to Fermilab.

“The sense of crisis was palpable, and I knew the availability of ventilators was critical,” said Christiano Galbiati, an Italian physicist who started the ball rolling on the project. “We had been doing some complicated projects in physics that required working with gases, and I thought it our duty to find a way to push oxygen into the lungs of patients.”

When the coronavirus attacks human lungs, the infection inflames cells and impedes the body’s ability to transfer oxygen from breathing into the bloodstream. For the sickest patients, a ventilator is needed to force oxygen through the lungs.

However, doctors and scientists in Italy were finding that COVID-19 patients were susceptible to serious lung damage if oxygen was pushed too hard or too fast, Brice said.

“It’s a pretty unusual disease,” he said. Much of the most complicated work in designing the Mechanical Ventilator Milano, as it’s been dubbed, involved the software and electronics needed to make a simple, cheap machine assert really precise control over the flow of oxygen.

The mechanics of the machine are not new, he said. “The real difference is the modern controls and software.”

Work was able to continue nearly 24 hours a day, Brice said, because the teams were on different continents. Italian scientists would work on coding for the software during the day and then hand off to Americans when night fell in Europe.

A total cost for the ventilators has not been set, Brice said, but the parts in each unit cost less than $1,000. Full-size hospital ventilators cost anywhere from $25,000 to $50,000.

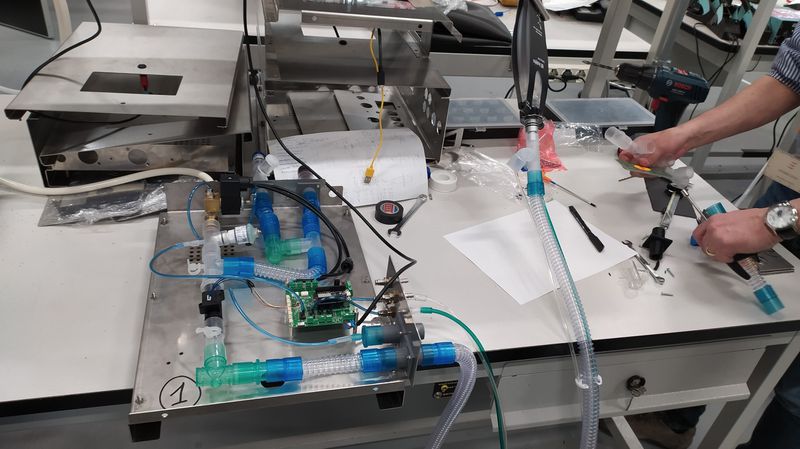

Fermilab scientists, collaborating with physicists around the world and an Italian manufacturer, have produced a low-cost ventilator that still offers the precision and controls of much more sophisticated and expensive machines. (MVM Collaboration/Fermilab/HANDOUT)

It’s unclear where need for the machines will develop first, given that the demand in the United States has ebbed slightly as infection rates in big cities have flattened out. However, Brice believes there will be global demand for the new ventilators as the pandemic spreads across the rest of the world.

“The need for ventilators has been a fluctuating story,” he said. “I think the need in Africa and Asia, and the Third World, for a fully functional yet low-cost ventilator — I fear there may be a significant need.”

For the roughly 15 Fermilab scientists, the project was a sprint to design and produce a ventilator in about a month. It was unlike anything they had ever done, Brice said. Across the world, 50 to 60 scientists were involved.

“It was energizing and it was exhausting,” he said. “Nothing has prepared us for this. Nothing like this, where 24 hours mattered. But nothing needed to be explained to anyone.”

While the experience may not have practical applications for Fermilab’s usual work exploring the deepest science of energy and matter, the team did learn a lot about teamwork and one another, Brice said.

“You learn a lot about your fellow scientists and fellow engineers because everyone is working in a zone outside of their comfort zone,” he said. “So you learn skills they have that you didn’t know they had.”